.jpg)

Molybdenum is a silver-white metal with a molybdenum atomic radius of 0.14 nm, an atomic volume of 235.5 px/mol, a coordination number of 8, a crystal of the Az-type body-centered cubic system, and a space group of Oh (lm3m), which has not been found yet. There are heterogeneous transitions. The lattice parameter of molybdenum at room temperature is between 0.31467 and 0.31475 nm, which varies with the impurity content. Molybdenum has a high melting point and ranks sixth in nature. It is called refractory metal.

Custom made machined Molybdenum Sheet/Plate/Foil

ASTM B386-91

Application: used for electron, aviation, spaceflight, electric light source, heating body in vacuum furnace, heat shield, molybdenum boat, molybdenum crucible, etc

Note: the adopts proprietary manufacturing process, the rolling production of hot and cold rolled high temperature molybdenum plate, sheet, with products, raised molybdenum in the crystallization temperature of 500 ℃ ~ 700 ℃, has higher temperature performance. Satisfy the vacuum furnace temperature 1850 ℃ heat shield material needs.

Parameter:

|

Grade |

Processing |

Condition |

Specification (mm) |

||

|

Thickness |

Width |

Length |

|||

|

Mo1

Mo2

Mola

TZM

|

Powder metallurgy |

Hard (Y)

Vacuum annealing (M) |

0.01~0.09 |

50~200 |

≥200 |

|

0.1~1.0 |

50~600 |

100~2000 |

|||

|

Hot rolled (R)

Vacuum annealing (M) |

1.0~30 |

50~600 |

100~1500 |

||

|

Thickness |

Tolerance |

Width |

Tolerance |

Length |

Tolerance |

|

|

ⅠGrade |

Ⅱ Grade |

|||||

|

0.10~0.15 |

±0.01 |

±0.02 |

50~200 |

±2.0 |

100~2000 |

±5.0 |

|

>0.15~0.30 |

±0.02 |

±0.03 |

50~500 |

±2.0 |

100~2000 |

±5.0 |

|

>0.30~0.50 |

±0.03 |

±0.04 |

50~600 |

±2.0 |

100~2000 |

±5.0 |

|

>0.50~0.70 |

±0.04 |

±0.05 |

50~600 |

±3.0 |

100~2000 |

±5.0 |

|

>0.70~1.0 |

±0.05 |

±0.08 |

50~600 |

±3.0 |

100~2000 |

±5.0 |

|

>1.0~2.0 |

±0.06 |

±0.10 |

50~400 |

±5.0 |

100~1200 |

±5.0 |

|

>2.0~3.0 |

±0.08 |

±0.15 |

50~400 |

±5.0 |

100~1200 |

±5.0 |

|

>3.0~4.0 |

±0.10 |

±0.20 |

50~400 |

±5.0 |

100~1200 |

±5.0 |

|

>4.0~5.0 |

±0.12 |

±0.30 |

50~400 |

±5.0 |

100~1200 |

±5.0 |

|

>5.0~30.0 |

±0.20 |

±0.50 |

50~400 |

±5.0 |

100~1200 |

±5.0 |

Molybdenum and its alloy rods and bars

Grade: Mo1, Mo3G (MoLa10), TZM (molybdenum alloy 364), molybdenum 360, molybdenum 361

Technical conditions: in line with GB/T17792-1999, ASTM B387-90

Application: Aerospace, electric vacuum, electric light source, rare earth smelting and glass melting.

Molybdenum wire

Grade:Mo1,Mo2

Standard:GB4182-84/ASTMB387-90

Parameter:

|

Grade |

Condition |

Diameter d(mm) |

200mm wire weight mg) |

200mmwire diameter tolerance (%) |

|

|

ⅠGrade |

Ⅱ Grade |

||||

|

Mo1

Mo2 |

Black |

0.02≤d≤0.03 |

0.65~1.47 |

±2.5 |

±3 |

|

0.03<d≤0.04 |

>1.47~2.61 |

±2.0 |

±3 |

||

|

0.04<d≤0.1 |

>2.61~16.33 |

±1.5 |

±3 |

||

|

0.1<d≤0.4 |

>16.33~256.2 |

±1.5 |

±3 |

||

|

0.4<d≤0.6 |

— |

±1.5 |

±2.5 |

||

|

0.6<d≤2.5 |

— |

±1.0 |

±2.0 |

||

Application: electric vacuum device, electric light source and wire cutting

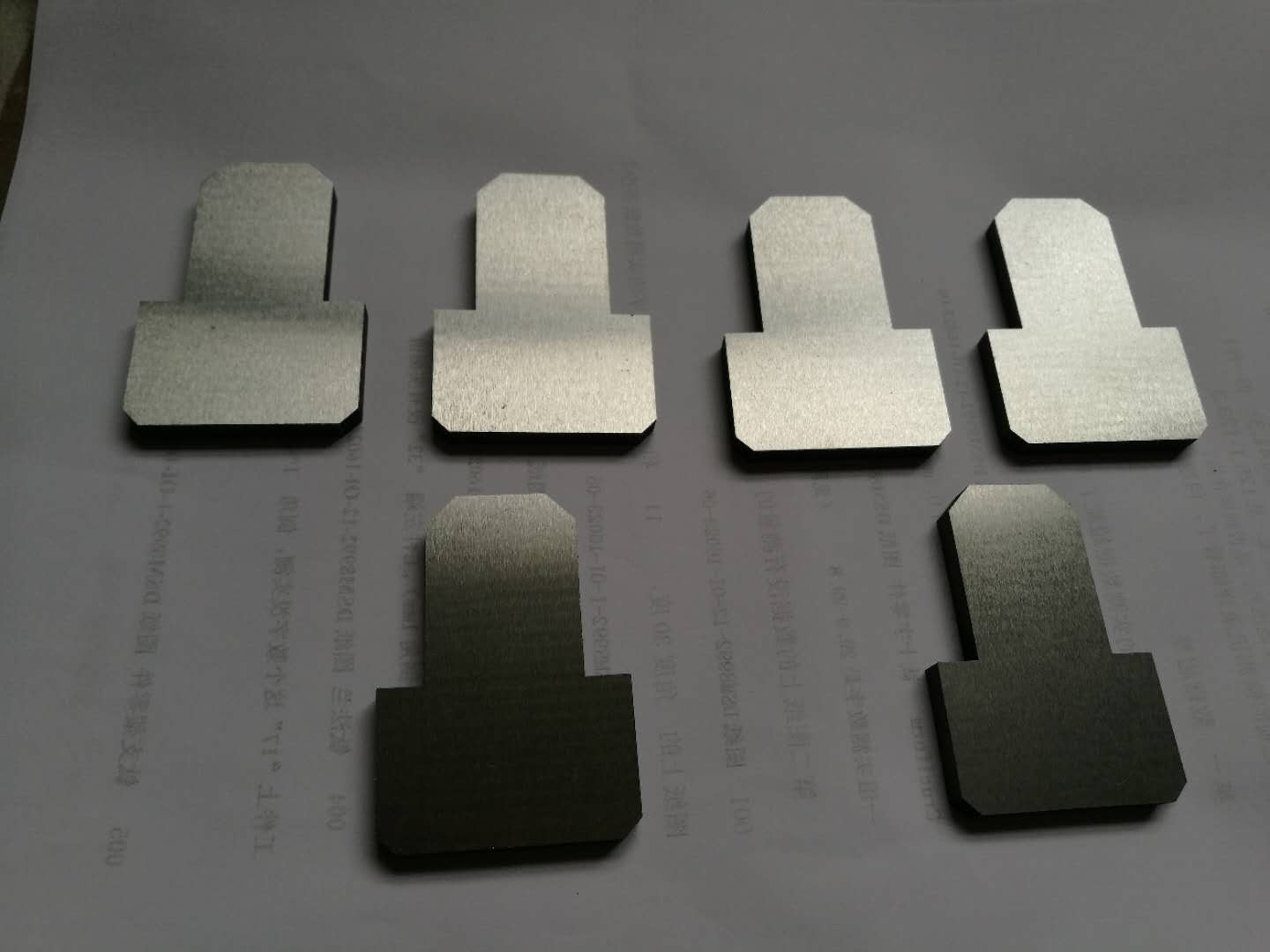

Molybdenum machined parts

Molybdenum CNC Machined Part

Material: Molybdenum and Molybdenum Alloys

Material characteristics: Great high temperature strength, special corrosion resistant to molten alkali metals and steam performance

Melting point: °C

Density : g/cm3

Surface: Polished

Drawing: 3D/ CAD

Size & Shape: Custom made

Raw material: Top quality Molybdenum rods, Sheets and Tubes

MOQ: 5 pcs

Surface: Polished surface

Roughness: Max 1.6um

Application

Assembly of high temperature equipment

Other equipment and industries that require super corrosion resistance

Molybdenum Bolts & Screws

Metric Molybdenum Bolts Standard: DIN, JIS, ISO, BS

Inch Molybdenum Bolts Standard: ANSI/ASME B18.2.1

Material: Molybdenum and Molybdenum Alloys

The Most commonly Specification and size used

|

Standard Item |

Size in Bulk Stock |

|

DIN 933 |

M8; M10; M12; M16 |

|

DIN 931 |

M8; M10; M12; M16 |

|

ANSI/ASME B18.2.1 |

1/4” ,3/8”, 7/6” 3/4” 7/8” 5/8” |

|

DIN 912 |

M8; M10; M12; M16 |

Application

Assembly of high temperature equipment

Internal fastening for Power plant equipment

Other equipment and industries that require super corrosion resistance

Molybdenum Crucible/Boats

Purity:≥99.95%

Molybdenum nuts as DIN/ISO ,M3-M36 MOQ:100pcs

Molybdenum crucible/boats :CUTOM made MOQ:5pcs

Application

Assembly of high temperature equipment

High temperature and normal pressure chemical reaction generator for precious metals

If you have any suggestions or opinions about our products,please leave a message,and we will immediately answer your questions. Thanks for your support.